Workpiece carriers are held back by stopper (AS) and are not introduced until the UDM turning unit has returned to its starting position.

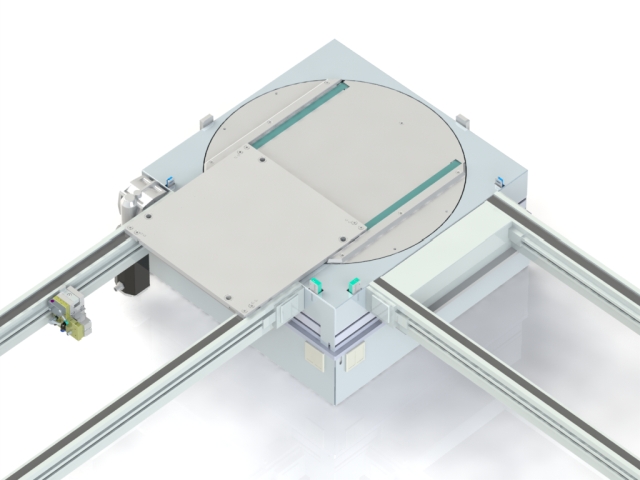

180° rotation version.

Turning unit (UDM)

A turning unit is used to alter the direction of workpiece carriers between two conveyors by 90° or 180°. An alternative to conventional corner transfer units, this turning unit facilitates flexible transport in the same direction: depending on the direction of rotation, the orientation of the workpiece carrier can be maintained or changed.

The workpiece carrier passes a light barrier as it enters the turning unit. When it reaches the end position, the belt drive is turned off and the position is detected by a proximity sensor. The workpiece carrier is then rotated through 90° to the left or right or turned 180° before the belt drive is reactivated, transporting the workpiece carrier through an exit light barrier to the next conveyor. The sensors and light barriers at the points of entry and exit monitor the system to ensure that no more than one workpiece carrier is on the turning unit.

The run-up and rundown of the drive motors (EC motors) can be controlled, as can the running speed. One motor drives the belt, while the other powers the rotary motion.

Click here for product film turning unit

Advantages:

- suitable as an alternative to a hub turning unit as no protective housing is required

- soft, smooth transport, as no height differences or uneven sections need to be compensated

- suitable as an alternative to a hub turning unit as no protective housing is required

Included:

- Turning unit with cover

- 2x drive motors

- Entry and exit light barriers

The following accessories are not included:

- Controls (STEIN Automation option)

- EC drive motor power supply unit (STEIN Automation option)

- Stoppers and stopping accessories (STEIN Automation option)

English

English Deutsch

Deutsch