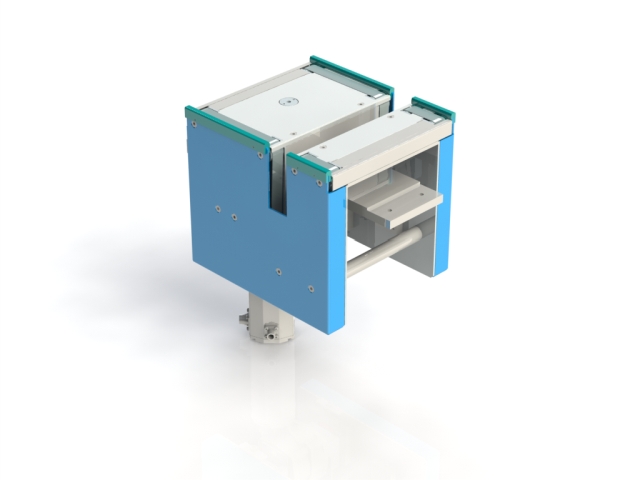

The transfer unit 1.5 in a 90° corner station. Design with angle bracket for the transverse section.

The transfer unit 1.5 used to redirect workpiece carriers along an outward branch in a system installed by a customer. The STEIN 300 conveyor has been adjusted to the height of the transfer unit 1.5. This minimises the distance that needs to be bridged.

Information:

3D details upon request.

Transfer unit 1.5

The 90° transfer unit serves the transport a workpiece carrier from the main belt onto a transverse section or vice versa. Lifting and lowering operations are pneumatic. Using appropriate sensors (not included), the system can detect when a workpiece carrier is fully on the transfer unit and the lifting or lowering process can begin. Once the transfer unit has moved away, sensors are able to confirm its position before it handles the next workpiece carrier.

Advantage and difference

The transfer unit 1.5 carries out the same functions as the U90° transfer unit, but it is also possible to transport a greater volume of workpiece carriers along the main profile of the conveyor. This is mainly necessary for small workpiece carriers in order to prevent them from tipping over when being transferred.

Included:

- Lifting device with sheet-metal protective coating

- Belt drive motor (AC or DC)

English

English Deutsch

Deutsch