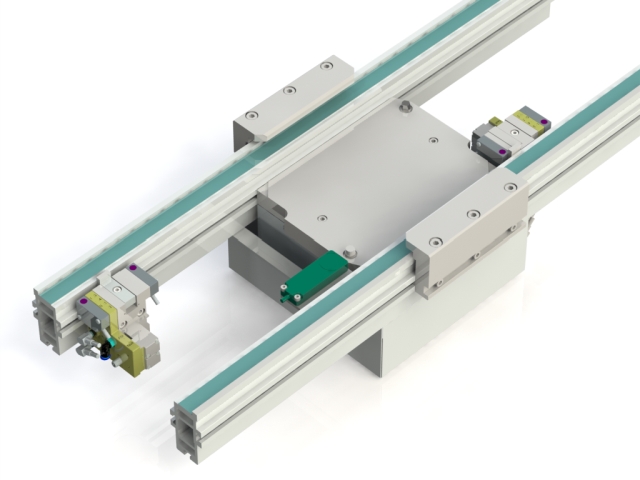

View from above. The workstation pre-stopper (ASI-AS) is at the top left. At the lower right is a workstation stopper (ASI-ASA), which brings the workpiece carrier to a halt before it can be centred and lifted by the HZE.

HZE with holding-down clamps in the lower end position.

Lift centring device (HZE) with holding-down clamp

Lift centring devices are installed in the STEIN 300 transfer system. In combination with the transfer system, HZE units with holding-down clamps facilitate the following operations:

- The precise positioning of workpiece carriers (and thus the workpieces they hold).

- Lifting and support of workpiece carriers during forceful processing operations on the workpiece.

- Exact vertical positioning thanks to the holding-down clamps.

- Preventing the unintentional withdrawal of a workpiece carrier during a processing task.

Other advantages of these units include:

- Less strain on the conveyor while workpieces are being processed.

- Reduced wear on the drive belt.

Workpiece carriers are brought to a halt by a stopper and pre-positioned. The entire lift centring device is then raised by pneumatics. The centring bold engages with the centring bushes on the workpiece carrier and precisely positions it with an accuracy of ± 0.02 mm. The entire workpiece carrier rests firmly on the base plate of the lift centring device and is gripped by holding-down clamps (not shown).

English

English Deutsch

Deutsch