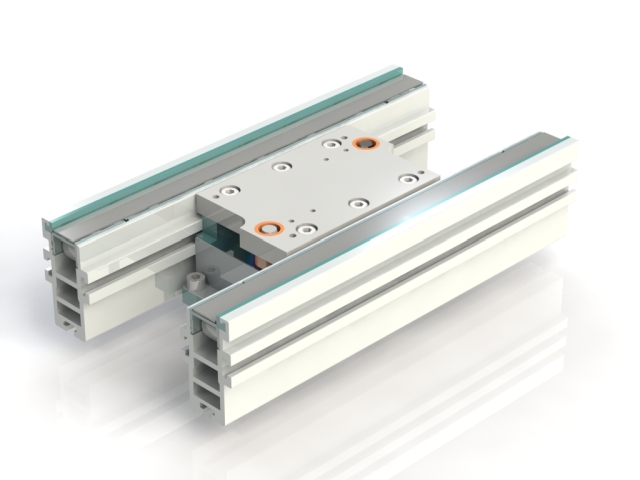

Spring guide rails (shown in yellow) are mounted in the conveyor to cover the height of the ZED, allowing the drive belts to slide past the workpiece carrier when it is subject to pressure.

The ZED housing consists of robust, smoothed steel plates and is preferably attached to an anvil with a contact plate..

Centring device (ZED)

Centring devices from STEIN Automation are optional modules for the STEIN 300.

The centring device (ZED) is ideal for applications in which a high force is exerted on the workpiece carrier in the Z-axis. Workpiece carriers are centred with an accuracy of 0.02 mm, and any forces that are applied are directed away from the conveyor system using an anvil plate (supplied by the customer). To enable this, spring guide rails are mounted in the belt profile in the area of the ZED.

A additional advantage of this mechanism is reduced wear on the drive belt because workpiece carriers do not rest on the belt during while the workpiece is processed.

The centring accuracy of the ZED is ± 0.02 mm.

English

English Deutsch

Deutsch